Functioning

Machine suitable for closing glass containers (jars and bottles) by means of TWIST-OFF CAPS.

Manufacturing features

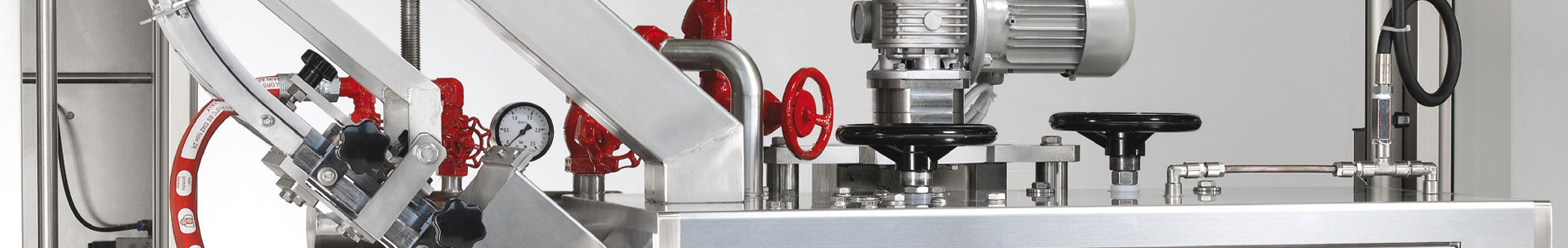

Basement in thick AISI 304 stainless steel plate with height adjustable feet.

Conveyor belt in AISI304 stainless steel, with table-top chain mounted on an antifriction section with adjustable side guides.

Side belts for containers dragging and steadiness.

Caps releasing and pre-screwing unit.

Steam sprigging unit for steam injection in the space between the cap and the container thread in order to soften the gasket and take the air away from the container head space, thus allowing the vacuum formation inside the container after closure.

Closing unit with variable speed flat belts.

The caps releasing unit and screwing unit are adjustable independently (as regards also to the dragging belts) by hand-wheels with a very simple and rapid operation.

Dragging and screwing belts centralised driving by geared motor.

Conveyor belt in AISI304 stainless steel, with table-top chain mounted on an antifriction section with adjustable side guides.

Side belts for containers dragging and steadiness.

Caps releasing and pre-screwing unit.

Steam sprigging unit for steam injection in the space between the cap and the container thread in order to soften the gasket and take the air away from the container head space, thus allowing the vacuum formation inside the container after closure.

Closing unit with variable speed flat belts.

The caps releasing unit and screwing unit are adjustable independently (as regards also to the dragging belts) by hand-wheels with a very simple and rapid operation.

Dragging and screwing belts centralised driving by geared motor.

Motorization systems driven by independent geared motors controlled and synchronized by inverter.

Head lifting system by an electro-mechanical unit for machine’s head height adjustment according to the containers height with max. and min. automatic safety devices.

Caps feeder equipped with hopper and driven by an independently adjustable speed motor.

Head lifting system by an electro-mechanical unit for machine’s head height adjustment according to the containers height with max. and min. automatic safety devices.

Caps feeder equipped with hopper and driven by an independently adjustable speed motor.

The feeder orients and conveys the caps towards the releasing unit where they are picked by the container.

A control system manages the machine according to the caps’ flow into the feeder as follows: “Too full” on the caps channel = feeder stop, “Too empty” on the caps channel = machine stop, “Caps feeding” = machine automatic re-start.

The machine is adjustable in all its parts to treat twist-off caps and glass containers of different dimensions.

The machine is adjustable in all its parts to treat twist-off caps and glass containers of different dimensions.

Electric control board in stainless steel.

Manufacturing in AISI 304 stainless steel, except for some parts which are in a different material suitable for their functioning.

After the start-up and first adjustments the machine does not need any operator intervention.

Manufacturing in AISI 304 stainless steel, except for some parts which are in a different material suitable for their functioning.

After the start-up and first adjustments the machine does not need any operator intervention.

technical data

| Output capacity: | 8.000 containers/h approx. with cap diam. 53 mm |

| Installed power: | kW 2,45 |

| Length: | 3.000 mm |

| Width: |

1.200 mm

|

| Caps dimensions: |

Ø mm 43 (with 4 fins) ÷ 110

|

| Containers dimensions: | Ø mm 40 ÷ 140 |

| h mm 40 ÷ 260 |

Equipment available on request: Releasing group for twist-off caps Ø 28 with 3 fins to 110 mm